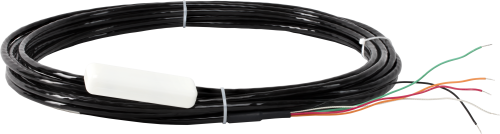

Epoxy housing is durable and easy to clean

Overview

The CS547A is a water quality probe that measures both electrical conductivity (EC) and temperature. It connects to a Campbell Scientific datalogger via the A547 interface. This probe is compatible with most Campbell Scientific dataloggers.

Read MoreBenefits and Features

- Compatible with most Campbell Scientific data loggers

- Easy to clean

- Corrosion resistant

- Rounded ends facilitate installation and removal

- Compatible with AM16/32-series multiplexers allowing measurement of multiple sensors

- Weighted option available for stand-alone submersion

Technical Description

The CS547A measures temperature with a thermistor. Electrical conductivity (EC) is measured with three cylindrical stainless-steel electrodes mounted in an epoxy housing. The electrode configuration eliminates ground loop problems associated with sensors in electrical contact with earth ground. The electrodes are ac coupled, and the datalogger applies a bipolar excitation. This process reduces electrochemical reactions, minimizes corrosion, and extends the probe’s life.

The CS547A is easy to clean and resistant to corrosion. It has rounded ends to facilitate installation and removal. The CS547A is shipped with a cell constant calibrated in a 0.01 molal KCl solution at 25°C. The solution has an EC of 1.408 mS cm-1.

Images

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR1000Xe | ||

| CR300 (retired) | ||

| CR3000 | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

The minimum pipe ID that the CS547A-L fits is 2.79 cm (1.1 in.).

Data Logger Considerations

The A547 Interface is required for connecting the probe to the data logger. This interface contains the blocking capacitors and bridge completion resistors necessary for the conductivity measurement.

A 3-ft cable is shipped with the sensor to connect the A547 to the data logger terminals. The CS547A requires one differential analog input, one single-ended analog input, and two excitation channels. One excitation channel must be capable of delivering ac excitation, so the BDR301 or BDR320 are NOT compatible.

Using Multiple CS547A Conductivity Probes

Special considerations apply when two or more CS547A probes will be measured by a single data logger.

A CR510 cannot be used to measure two probes because it does not provide sufficient (three) excitation channels.

Although it is acceptable for the two thermistors to share an excitation channel, each conductivity measurement requires a dedicated excitation channel. If excitation for the conductivity measurement were to be shared from a common excitation channel, both solutions would become polarized and once excitation was removed, some charge could be transferred from one solution to the other making the measurements interdependent on one another. If more than two CS547A probes are to be measured, then an AM16/32-series multiplexer is required.

Multiplexers

If more than two CS547A probes are to be measured, then an AM16/32-series multiplexer is required. In this scenario, each probe is wired to the multiplexer and one A547 interface is wired between the multiplexer and the data logger. If the system were maximized, up to sixteen CS547As could be connected to the multiplexer. However, because the A547 becomes a part of the measurement circuit for all connections to the multiplexer, only CS547A probes could be connected to the multiplexer (i.e., it is not possible to mix other sensor types with the CS547As attached to the multiplexer).

Specifications

| Output | Analog (requires A547 interface) |

| Conductivity Measurement Range | ~0.005 to 7 mS/cm |

| Temperature Measurement Range | 0° to 50°C |

| Conductivity Accuracy |

|

| Temperature Polynomial Linearization Error | Typically < 0.1°C (over 0° to 48°C) |

| Thermistor Interchangeability | Typically < 0.2°C (over 0° to 50°C) |

| Wetted Materials | Epoxy housing, 316 stainless-steel rings, polyurethane cable |

| pH Operating Range | Solution pH of less than 3.0 or greater than 9.0 may damage the stainless-steel housing. |

| Operating Temperature Range | 0° to 50°C |

| Depth Rating | 305 m (1000 ft) maximum |

| Dimensions | 8.9 x 2.54 x 1.9 cm (3.5 x 1 x 0.75 in) |

| Weight |

|

| Weighted Cable Weight | 80 g (2.8 oz) |

Resources and Links

Downloads

CS547a Program Examples for CR1000X and CR1000 Data Loggers v.1 (7 KB) 24-02-2022

Four programs are included: two CR1000X programs and two CR1000 programs. The first CR1000X and CR1000 programs measure the sensor and correct for cable resistance, EC ionization, and temperature. These programs use constants for KC (printed on the sensor label), cable length, and temperature coefficient (see manual). These values should be changed to fit your sensor. Also included are a CR1000X and a CR1000 program for calibrating the sensor. Newer data loggers such as the CR6 are programmed similarly to the CR1000X. Older data loggers such as the CR800-series and CR3000 are programmed similarly to the CR1000.

FAQs for

Number of FAQs related to CS547A-L: 18

Expand AllCollapse All

-

Yes. Each CS547A-L is shipped with a pn 7785, 4-inch Nylon brush.

-

The readings will be accurate for the sample of water inside the cavity, but that may or may not be indicative of the overall conductivity of the well. Flowing water allows a more representative measurement over time.

-

Position the CS547A-L so that it is protected during high flow but remains submerged at base flow. Orient the measurement cavity parallel to the water flow.

-

The CS547A-L has a built-in thermistor that is used for this purpose.

-

An analog voltage signal of no more than 2500 mVdc.

-

If the measurement cavity is kept clean, ephemeral conditions should not affect the reading.

-

The sensor should never need recalibration under normal use unless the diameter of the measurement cavity changes because of corrosion or abrasion. For more information, refer to the “Factory Calibration” and “Field Calibration” sections of the CS547A instruction manual.

-

Ice forming inside the hollow cavity can damage the sensor; therefore, as a precaution, the sensor should be removed.

-

Two CS547A-L sensors can be wired directly to one CR1000. One A547 interface is needed for each sensor, unless a multiplexer is used. A multiplexer switches all sensors through one A547 interface.

The CS547A instruction manual offers this warning: "Wire the conductivity excitation and temperature excitation lines in different excitation ports or measurement errors will occur. If multiple CS547A/A547s are wired to one data logger, each conductivity excitation must use a separate excitation port. However, you can wire multiple temperature excitation lines into the same excitation port."

-

Exciting the CS547A-L with an electrical charge to make a measurement causes ionization. The ionization correction code corrects for this disruption.

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences